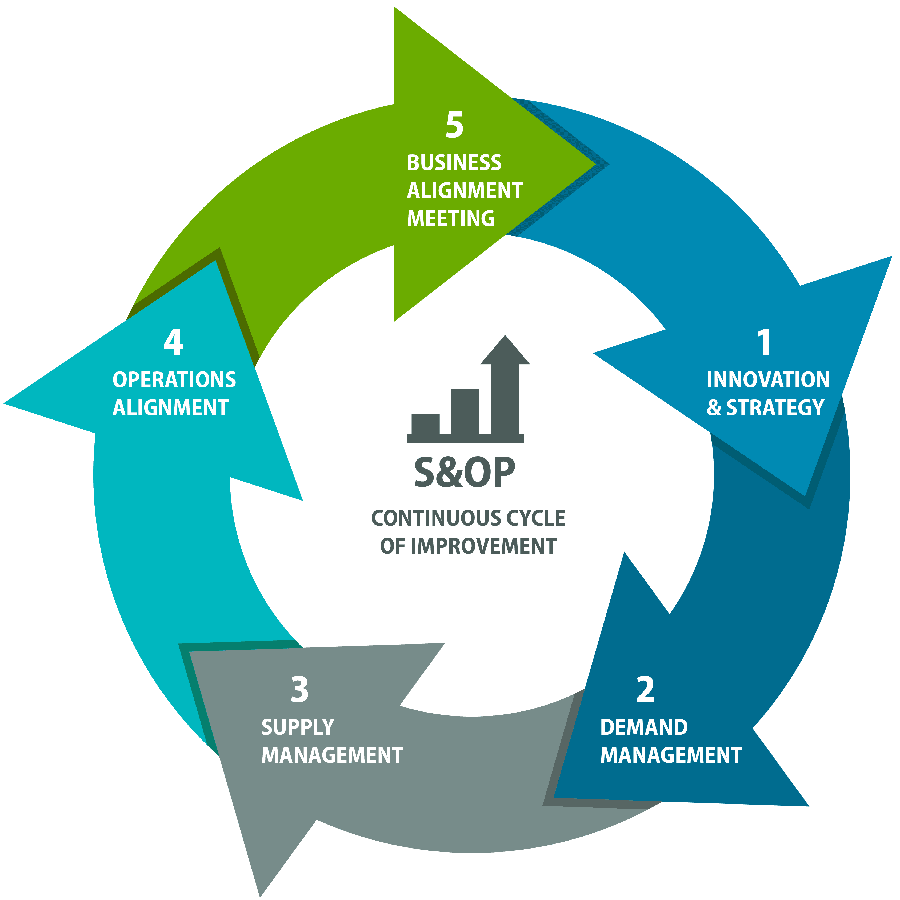

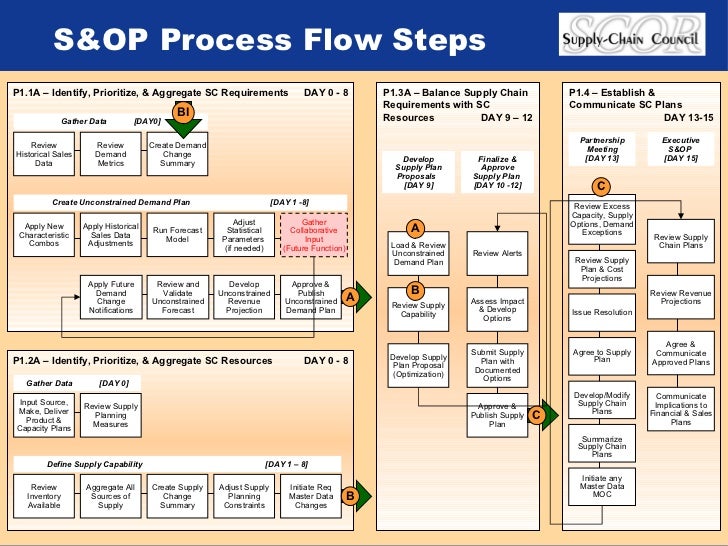

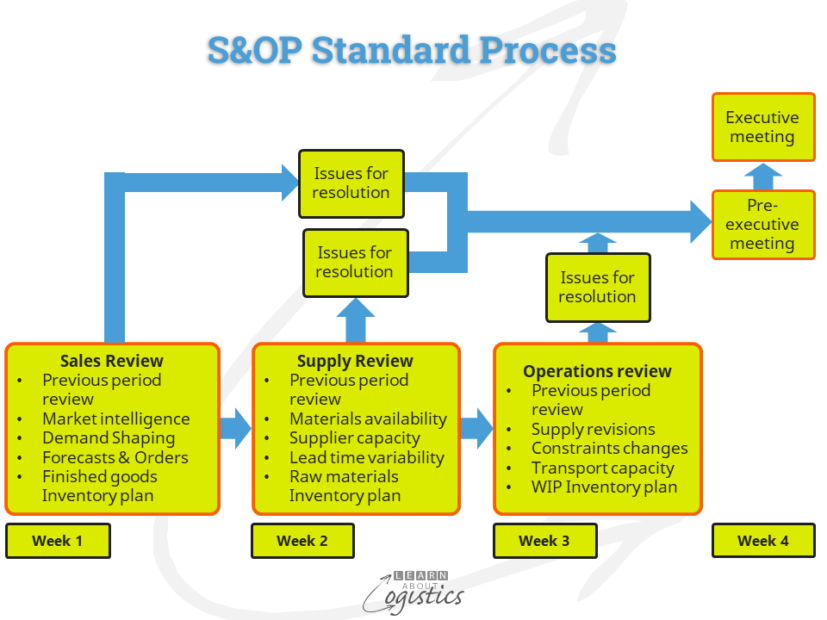

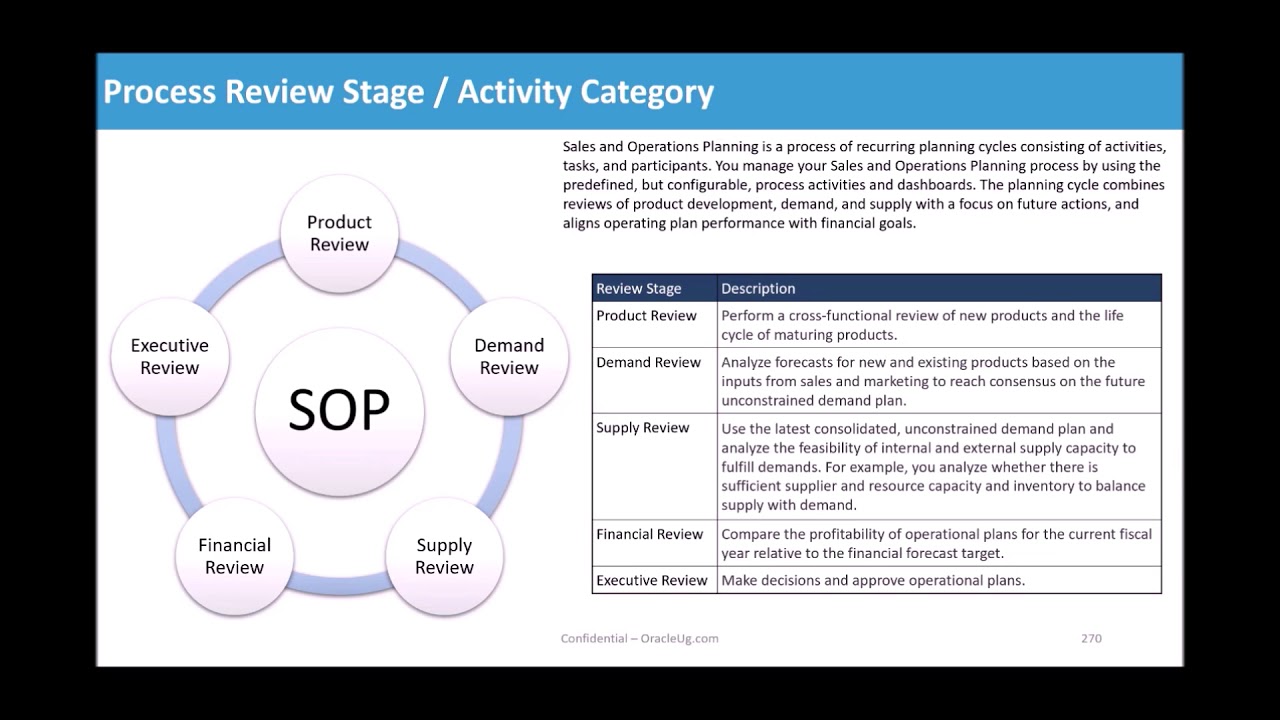

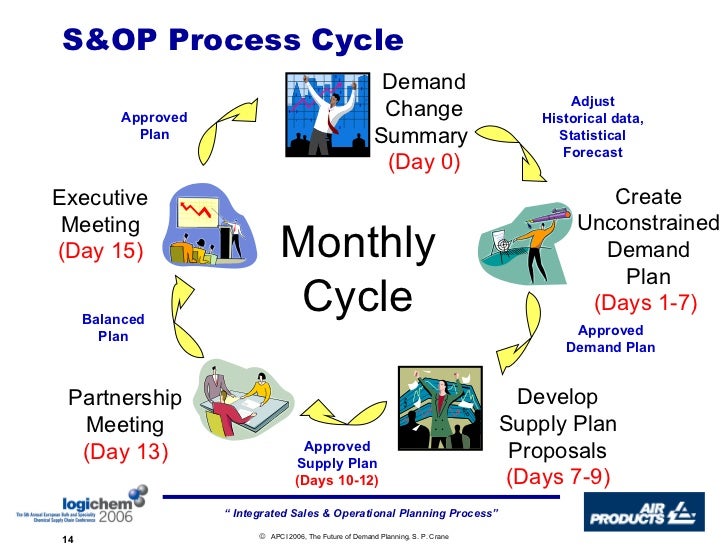

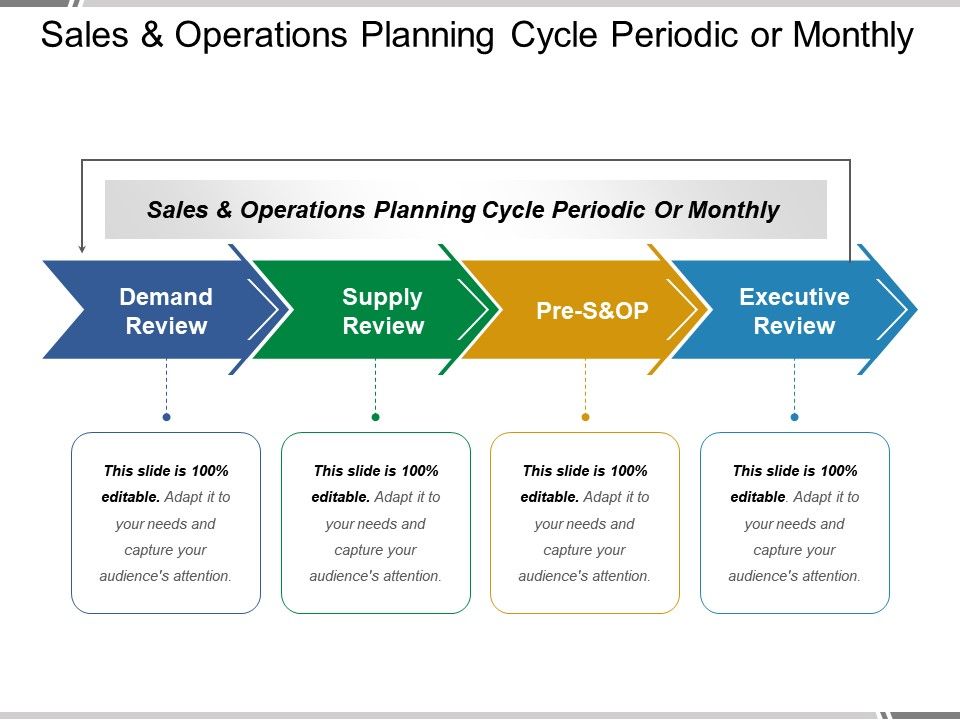

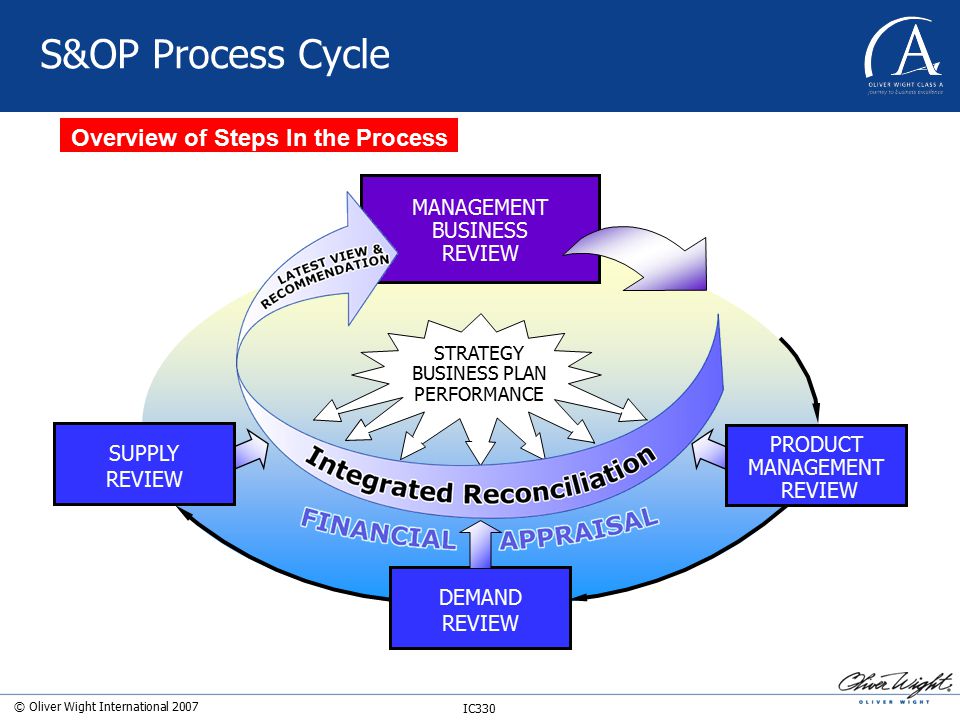

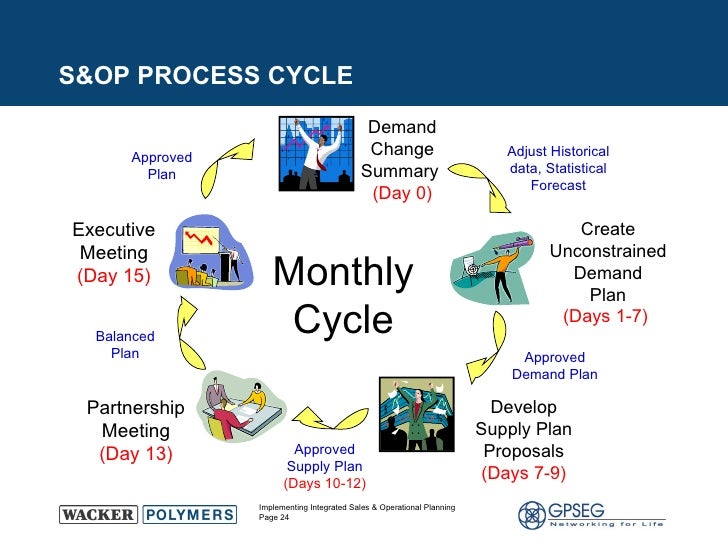

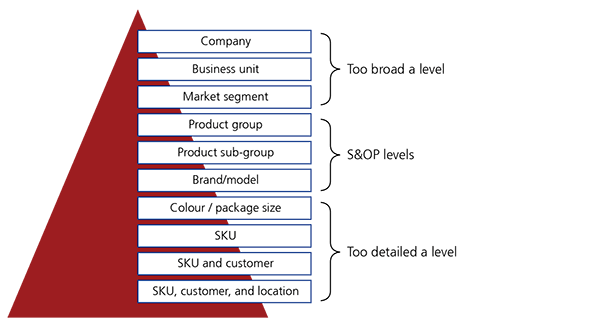

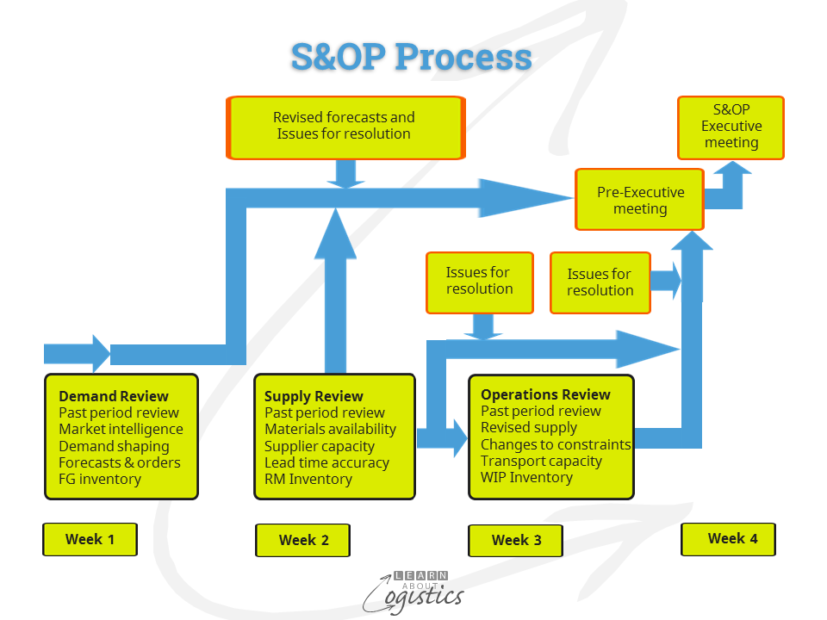

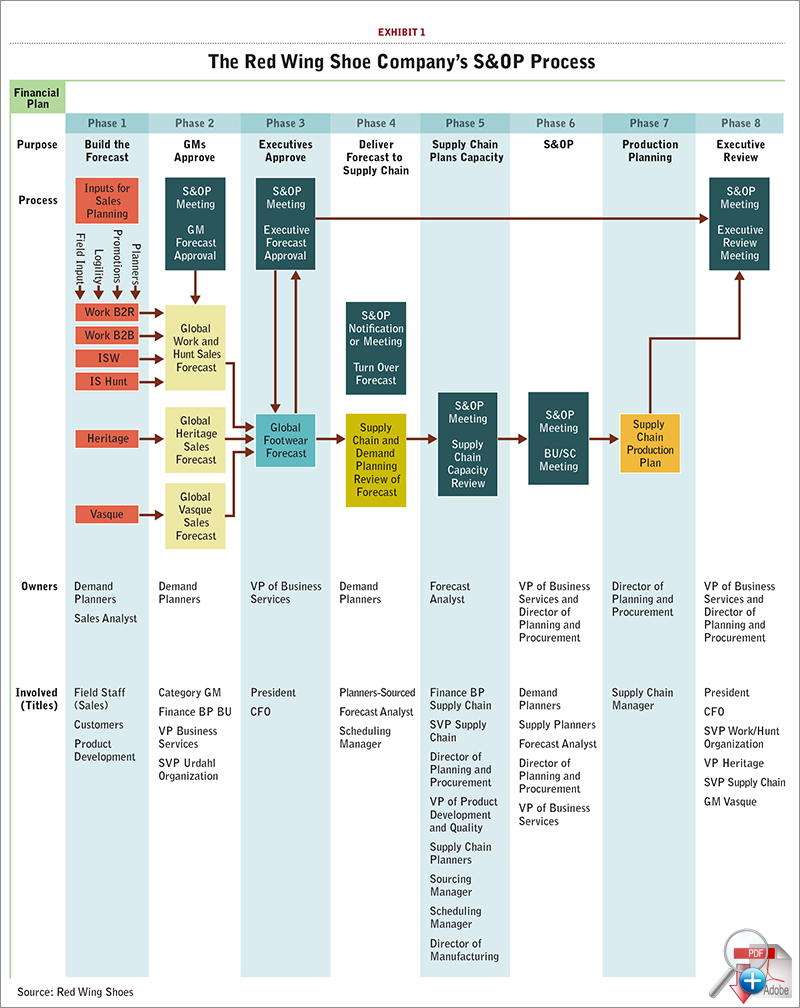

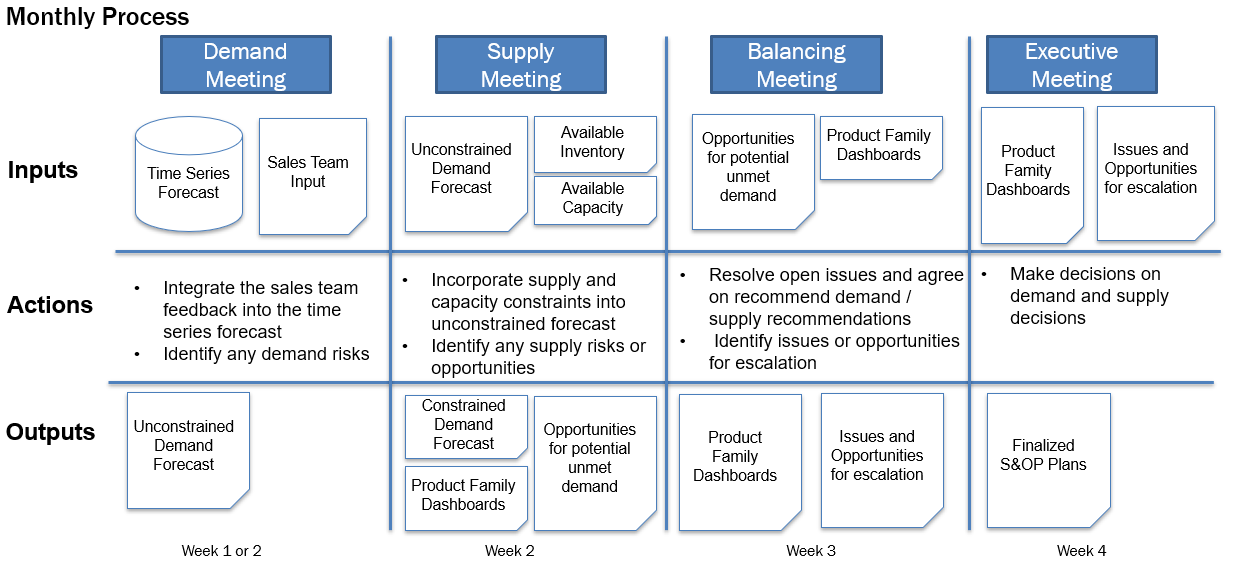

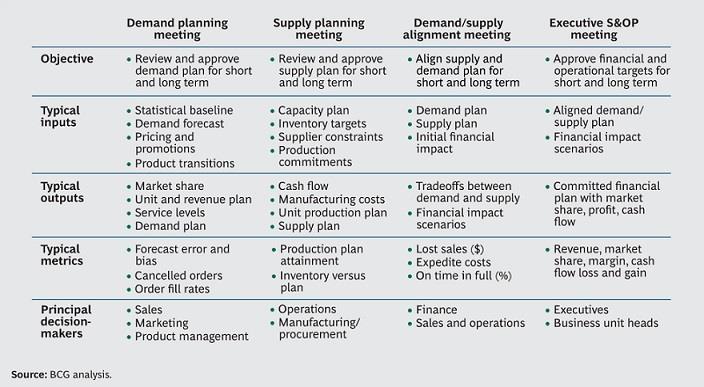

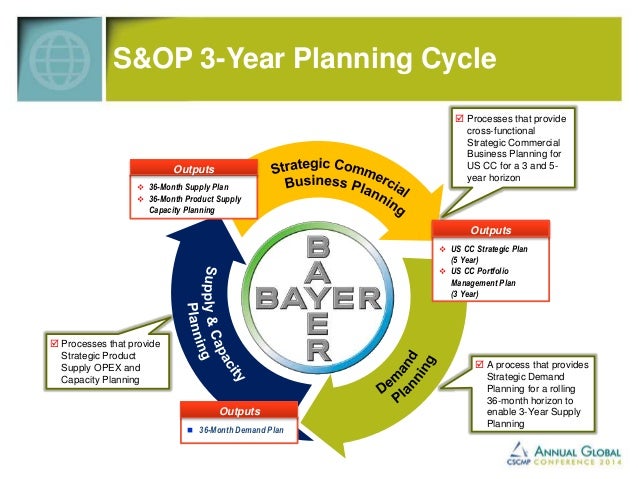

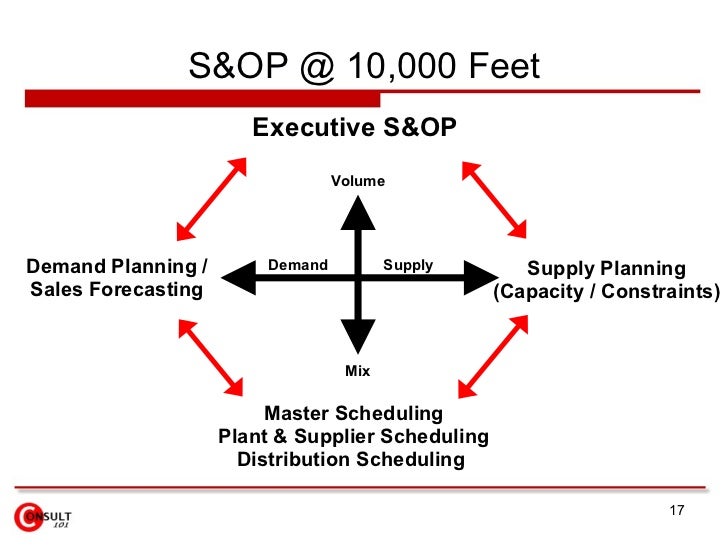

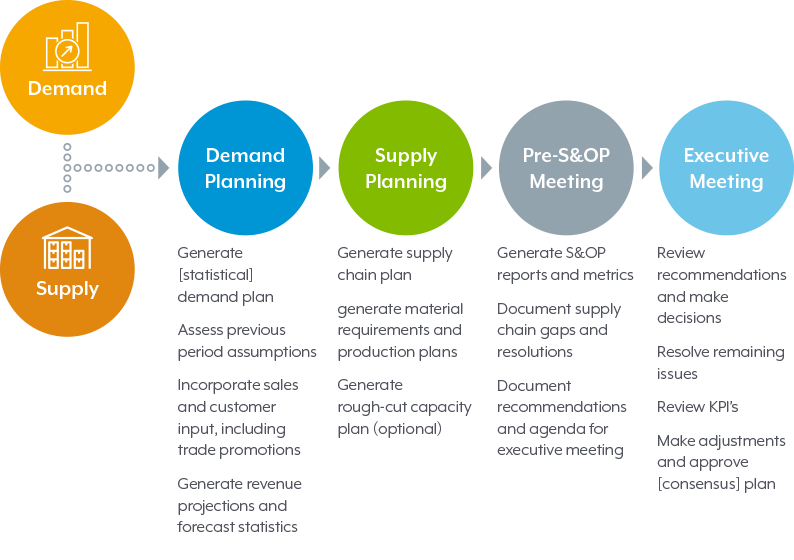

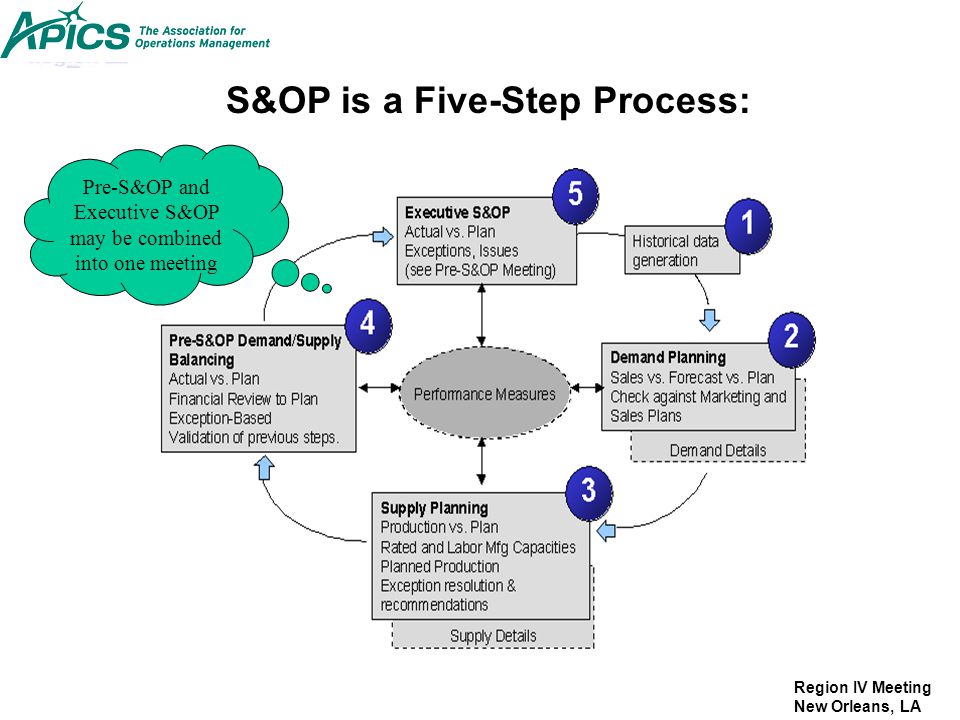

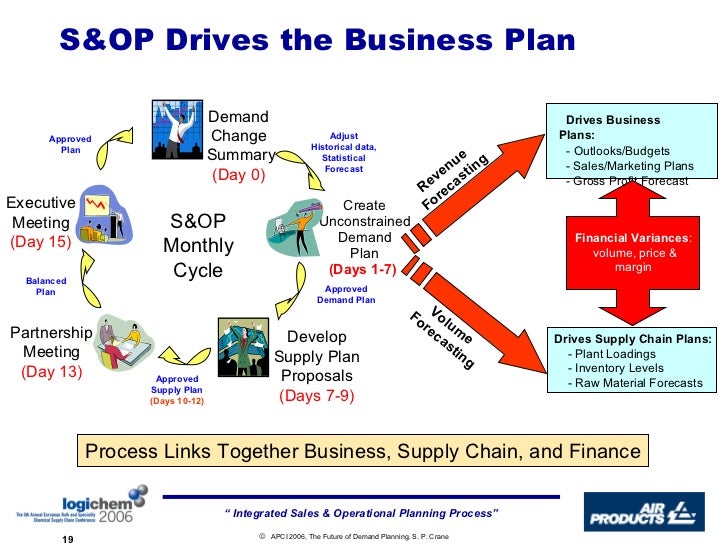

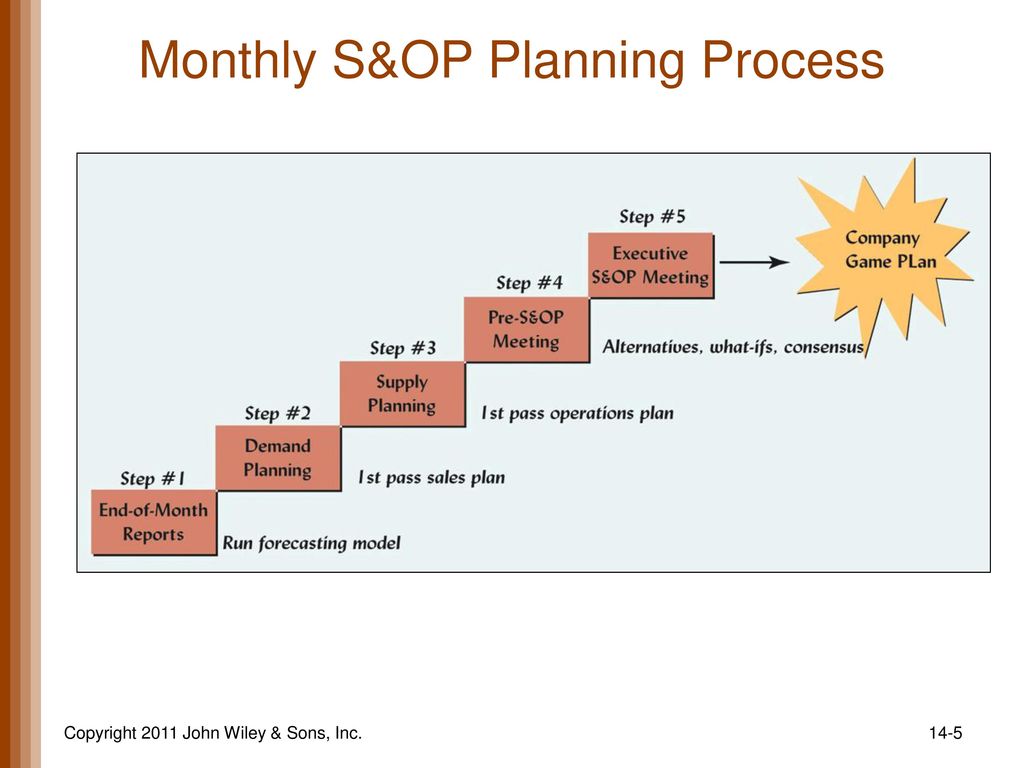

Each month or planning period, the S&OP demand and supply planning process follows a very specific linear work flow as outlined in this article Setting a planning hierarchy is a critical part of generating appropriate forecasts The demand planning hierarchy is top down one to many within the sales level and also within the product levelBe familiar with the S&OP process and terminology used in OMP;The Executive S&OP planning cycle is monthly, with provisions for midperiod revisions when major changes occur Executive S&OP is an aggregate planning tool It focuses on aggregate volumes, and only rarely looks at issues of mix, ie individual products, stock keeping units, customer orders and

Sales And Operations Planning Explorescm

What are the basic elements of the s&op process

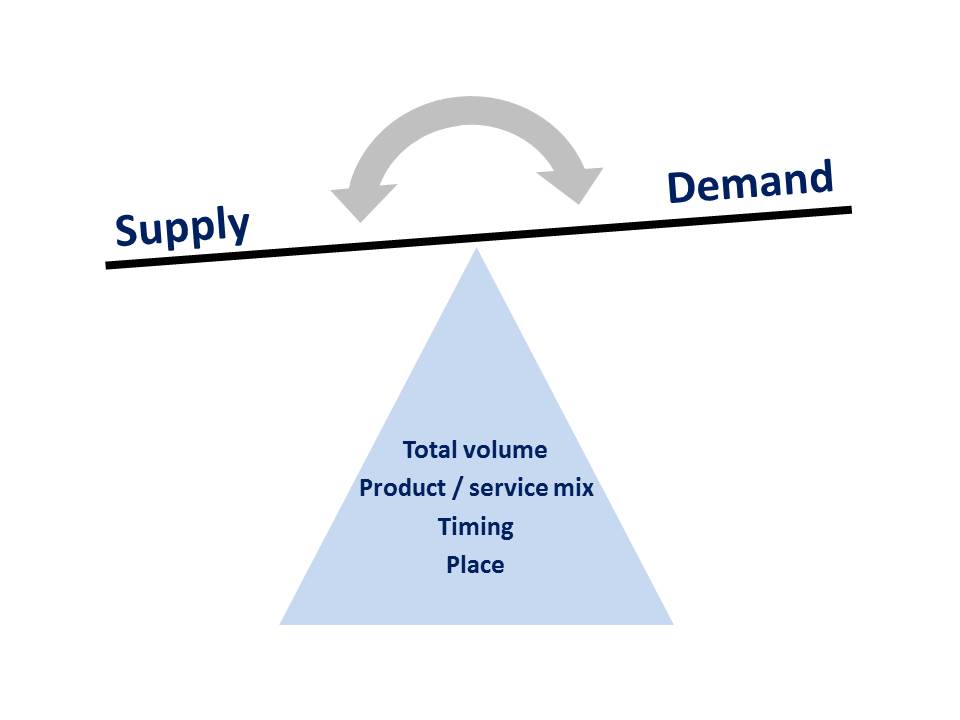

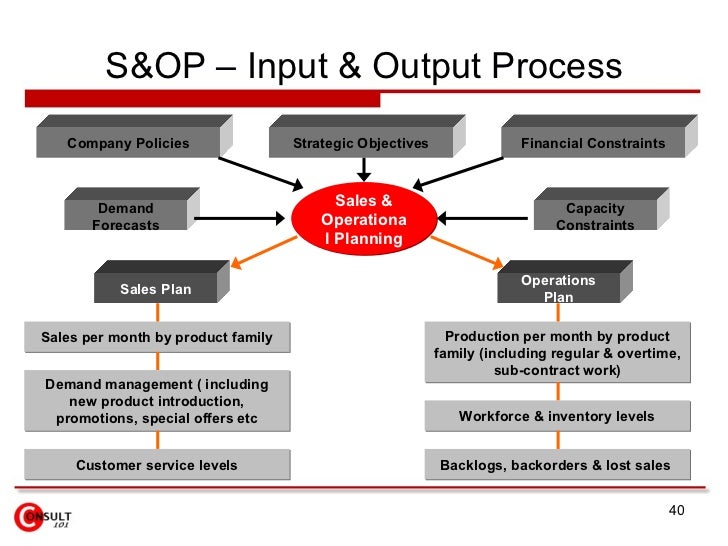

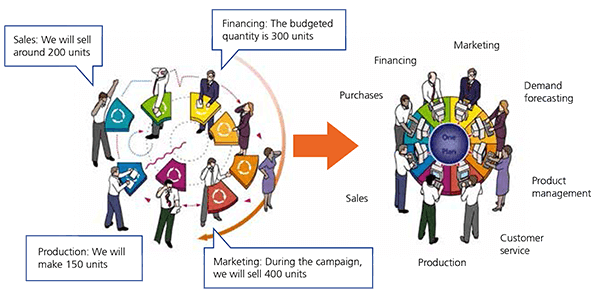

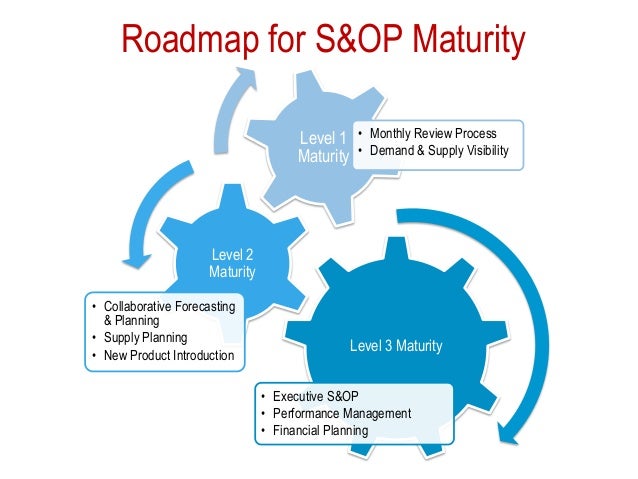

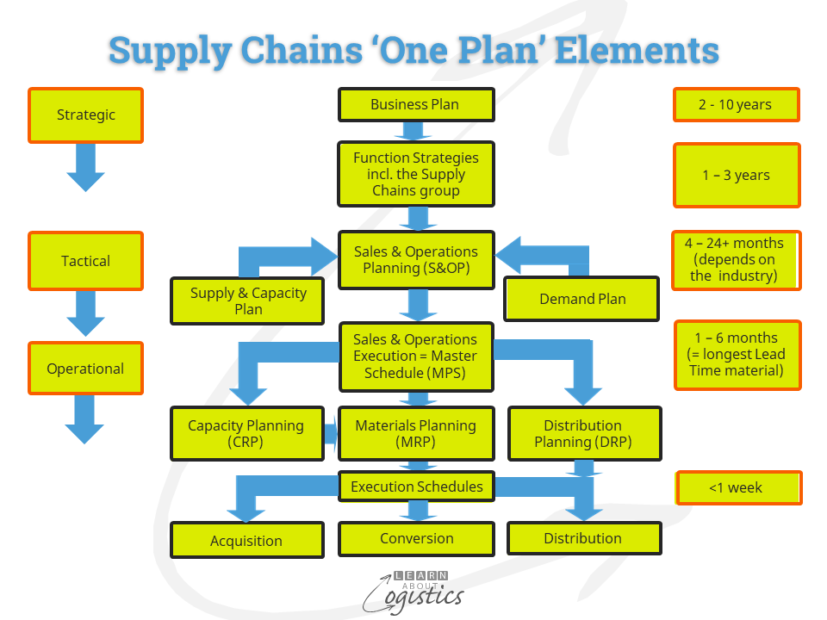

What are the basic elements of the s&op process-Jan 01, 19 · S&OP is described as a crossfunctional long term planning process that links different business plans into one integrated set of plans with the main purpose of balancing supply and d mand and linki g the strategic plans to the operational plans of the firm 4S&OP develops a midrange plan to operations using input from top management The plan identifies key resources to achieve the firm's strategic objectives and goals, and is the basis of all subsequent material and labor resource

What Is S Op How S Op Works Demand Planning Com

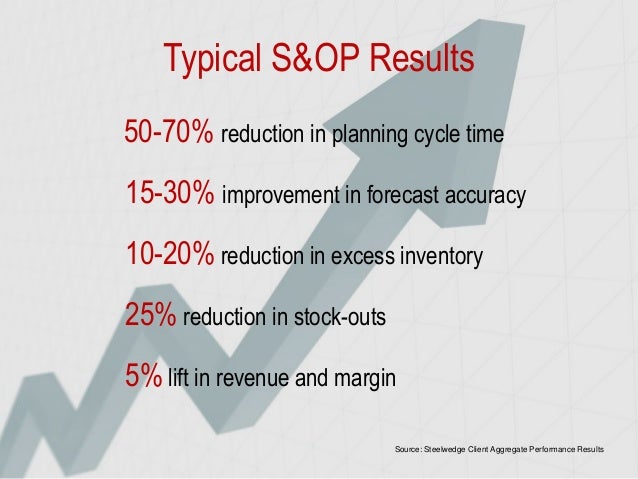

Sales and operations planning (S&OP) is a crucial process for any business — especially postCOVID, as plenty of businesses have seen pipeline shrink and sales cycles lengthen S&OP is about making sure that sales don't just generate revenues for the business, they generate profitsAug 30, 19 · The same is true for supply chain planning Sales and operations planning (S&OP) focuses on a tactical horizon from 324 months and has completely different objectives than sales and operations execution (S&OE), which covers the near termDec 11, 09 · S&OP – Policies Policies Planning process & how demonstrated capacities by product family will be maintained and utilised Schedule of future meetings, attendees, & an agenda for a monthly review meeting Inventory, backorder, backlog plan, planning fences, service levels, new product intro, promotion, special offers etc Product families & variances analysis how the

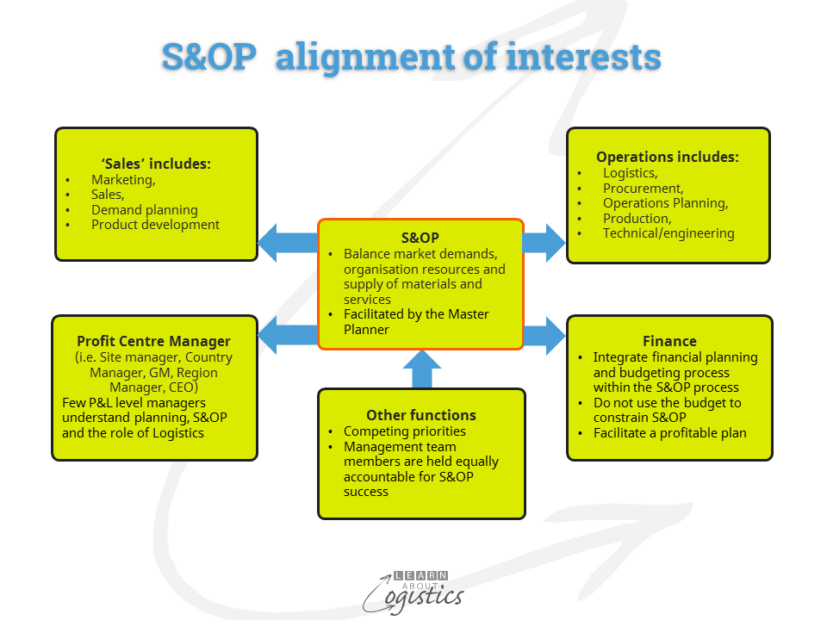

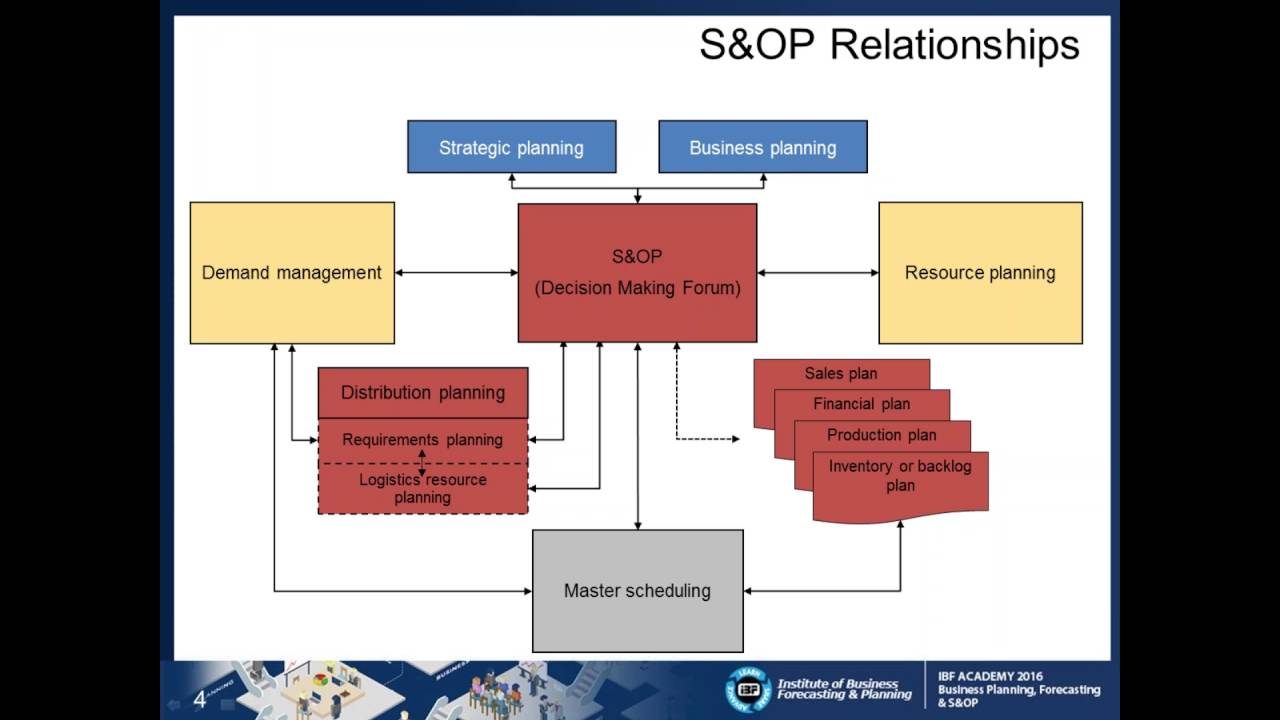

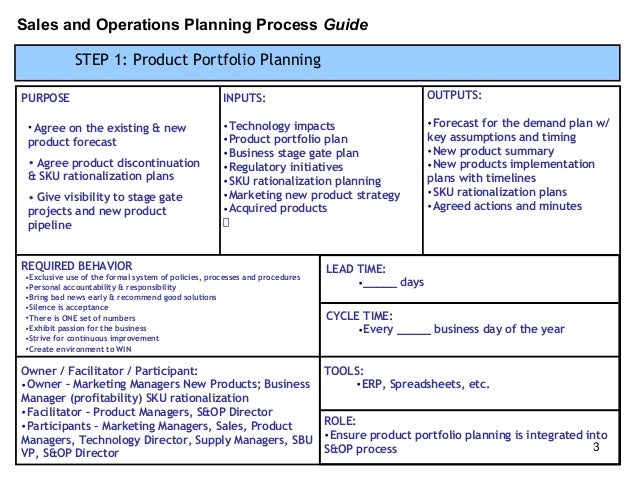

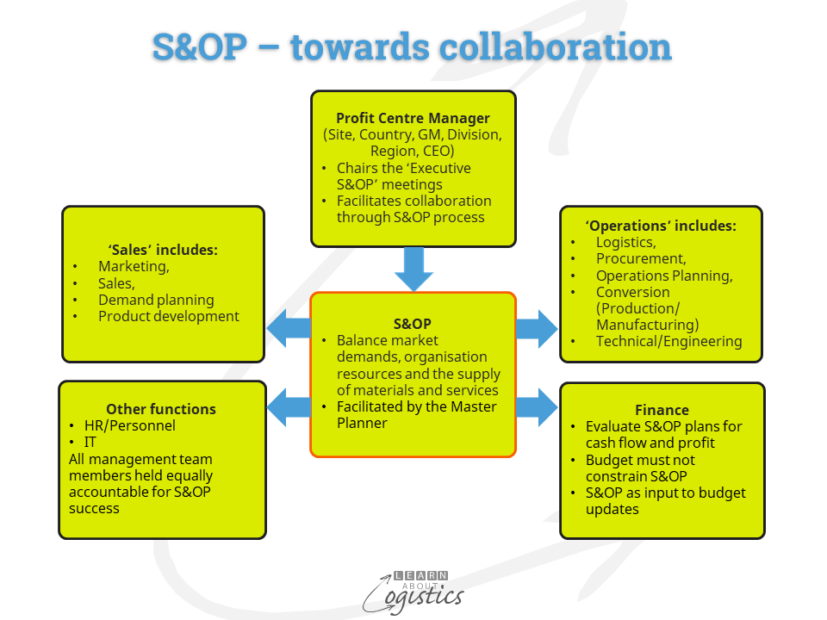

According to IBF, S&OP is a process that coordinates different areas of the business to meet customer demand with the appropriate level of supply When establishing your process, it is important to consider who will be responsible for each step of the process You will also want to set expectations for handoffs, meetings, and how you will communicate changes Effective S&OPThere is a planning process that is specifically designed to bridge the chasm between the twoNov 13, 12 · The segmentlevel S&OP process is the most important tactical planning process inside any business The purpose is to implement the business strategy in each market segment The gotomarket strategy comes to real life inside the S&OP process Each functional area has a specific role and is engaged in the overview of the whole business

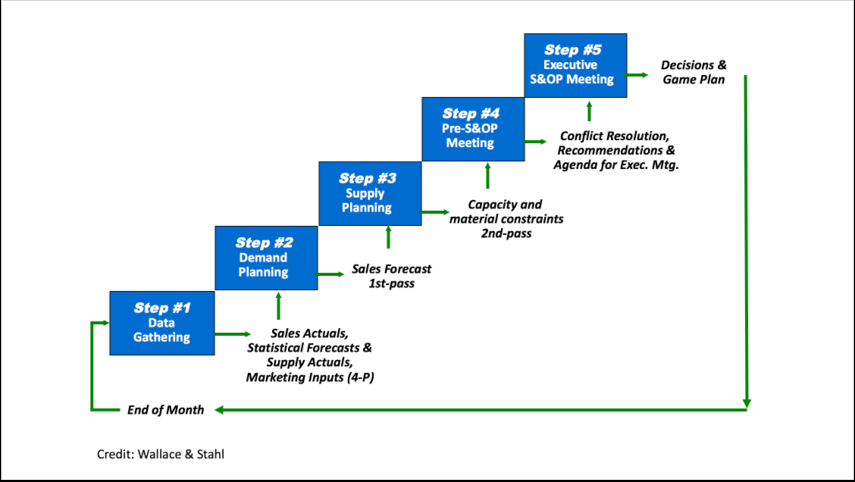

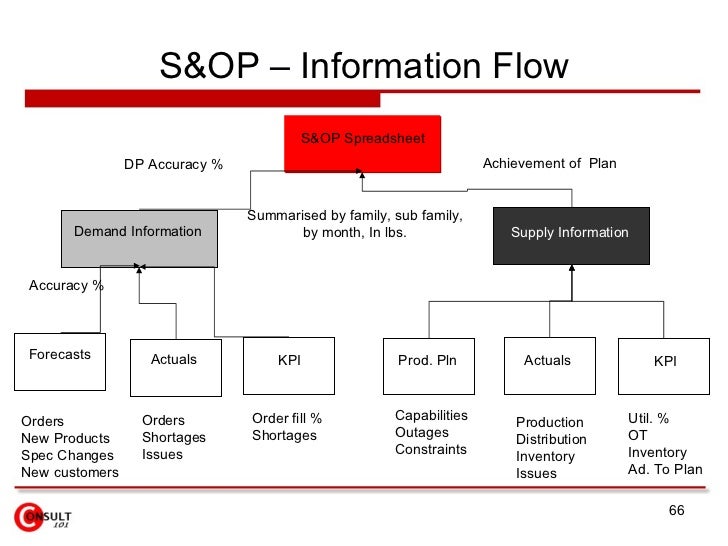

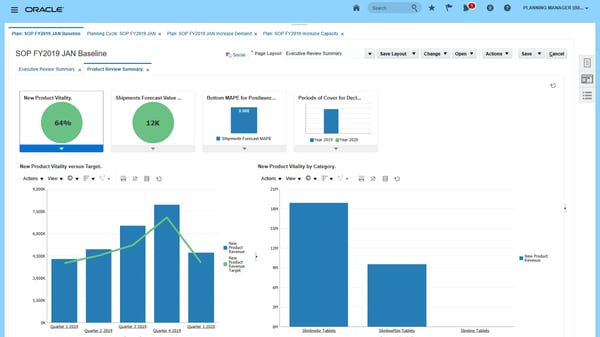

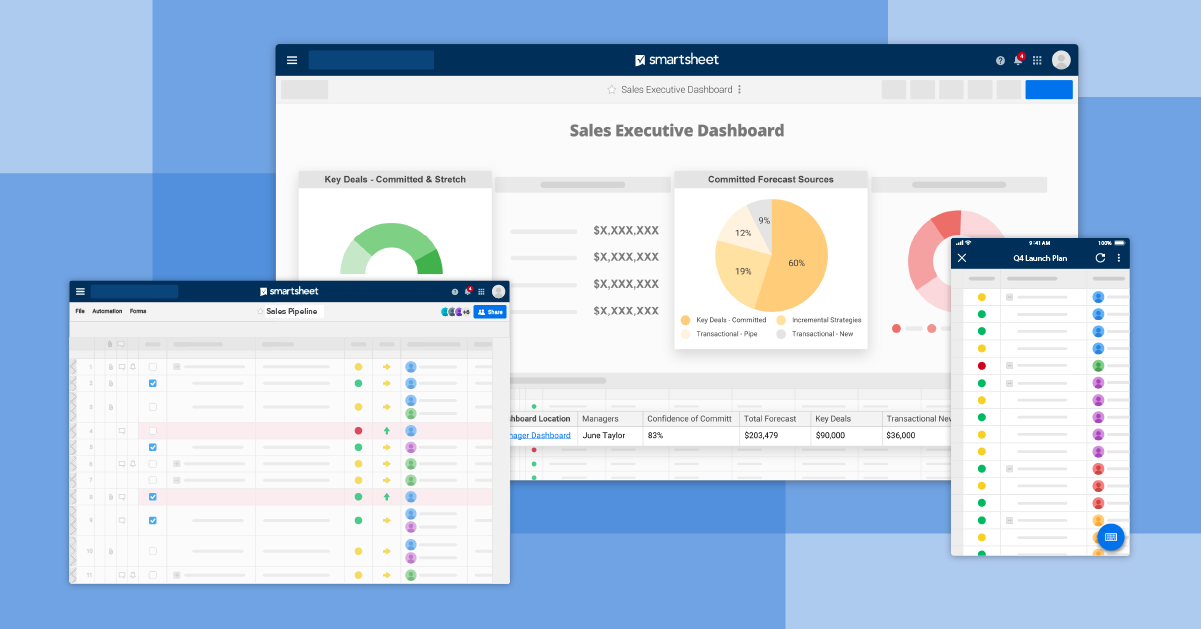

Step one of the S&OP planning process is data collection, or gathering information from different department of the company This could include things like former and current sales trends orAn effective sales and operations planning (S&OP) process guides business decisions, provides key problem solving strategies, gives executives greater control over the enterprise and drives overall business success Establishing and sustaining highfunctioning S&OP processes within an organization can be extremely difficult, howeverBe able to navigate through the components of typical S&OP dashboards ;

S Op Sales And Operations Planning And Sco

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Oct 27, 18 · S&OP deals with the continuous change that occurs in the business and is a process to effectively manage ongoing change In practice, it is called a replanning process S&OP is owned by the GM or CEO It is a crossfunctional process and includes all the functions of the company Correctly implemented, it is a demand and strategydriven processS&OP process is guided by output from strategic planning and, in turn, drives daily operations This makes S&OP the "linchpin" planning process, connecting strategy to execution Obviously, this is a critical planning process for any business The accuracy of S&OP plans invariably determines how well a company achieves itsTo accomplish the demand and supply balance Sales and Operations Planning Steps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps

Optimize Sales And Operations Planning S Op With Slim4 Slimstock

S Op Sales And Operations Planning And Sco

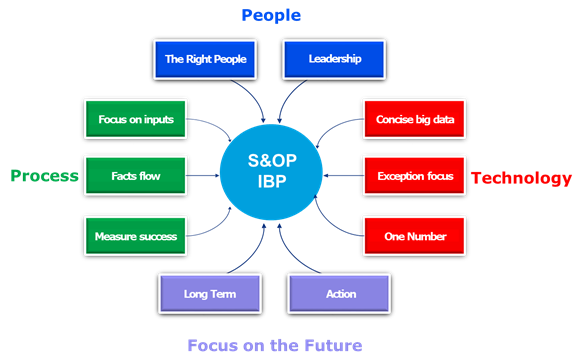

Sales and operations planning is typically led by senior management and is most often executed monthly It is an iterative process in which results from one planning cycle are compared with the next to provide management with trend information from across the businessOperational planning – Rolling twelve months, reviewed monthly Translates tactical plans into specific objectives and confirms activities and timings through shortterm plans and execution Goal of S&OP process The primary goal of the sales and operations planning process is to facilitate the flow of information between demand and supplyIntegrated Business Planning (IBP) is the process of integrating sales, finance, product supply teams and processes into one planning cycle with insights to drive a close alignment between opertational efficiency, agility and strategic business performance Sales and Operational Planning (S&OP) is widely adopted across the consumer

Implementing An Integrated Sales And Operations Planning Process

Sales And Operations Planning Cycle Chainsequence Inc

Demand Planning Made Easy At the end of the day, S&OP is a process and not a technology However, demand planning is made easy by technology Although we were refining our processes and redefining the roles of our people, we were still working with spreadsheetsApproaches to the Sales and Operations Planning Process While approaches vary among industries and companies, they typically focus on a monthly S&OP planning process with a longterm planning horizon ranging from 18 to 36 months The annual overall business plan ties in with all other company plans, which are regularly reviewed for alignmentAug 03, 19 · The menus are fourweek cycle menus with a breakfast, lunch/supper, and snack Menus are customizable and contain links to standardized recipes Your institution can start implementing these healthy seasonal menus in your adult or childcare facility today!

What Is S Op How S Op Works Demand Planning Com

Sales And Operations Planning Nengu

Jun 29, · Sales and operations planning (S&OP) is an integrated business management process through which the executive/leadership team continually achieves focus, alignment and synchronization among all functions of the organizationSales & Operations Planning (S&OP) The critical success factors Warehousing & distribution Customer Manufacturing Sourcing Assets & facilities Transportation Fast, effective process to assess the operations & financial impact and the best possible response v Single, organization wide demand & supply planning vi High costs savingsPlanning (Advanced S&OP) process is a consensus on one set of operating numbers that the members of the executive team hold themselves accountable to execute It includes an updated sales plan, production plan, inventory plan, customer leadtime

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

Implementing An Integrated Sales And Operations Planning Process

S&OP Enhancement Demand Planning & New Product Introduction Product Life Cycle Planning Inventory Control Warehousing & Distribution Management of 3PL and Contract ManufacturingUnderstand the S&OP functionality and be able to perform the actions carried out during the cycle;The Uptown CycleLink is the result of 4 years of planning, public engagement, and an evaluation of every block and corridor in Uptown Charlotte The initial result of that evaluation was the Uptown Connects study , which was published and presented to City Council in the summer of 17

Supply Chain Management Sales And Operations Planning S Op Improvement 27 Slide Powerpoint Flevypro Document Flevy

A Common S Op Process For Your Business Helps Planning Learn About Logistics

It is not a "silver bullet" that could somehow magically fix existing issues, but a powerful enhancement that must work hand in hand with a strong S&OP process Sales and Operations Planning (S&OP) is a powerful approach that seeks toThe S&OP planning process should always be built on a realistic foundation, as the base line determines the trustworthiness of the S&OP plan That is why the operational plan should integrate towards IBP for S&OP (preferably via HANA Cloud Integration, HCI) HCI allows you to integrate data from your legacy system to IBP for S&OP applyingIntegrated Business Planning (IBP) is the business planning process that extends the principles of Sales and Operations Planning (S&OP) throughout the value chain It is to create a bridge between strategy and execution IBP is a next step for companies that already have an S&OP process

What Is Sales And Operations Planning S Op Plex Demandcaster

S Op A New Frontier For Supply Chain Resilience 05 14 Cscmp S Supply Chain Quarterly

CACFP Fall Cycle Menu (PDF, 371 KB) CACFP Winter Cycle Menu (PDF, 344 KB)Navigation in OMP getting started;Mar 02, 21 · The S&OP process focuses on the tactical horizon, typically from 3 to 18 or 24 months When developing the process timing, the key point in the calendar is the existing business planning meeting This has to become the executive S&OP meeting, and the process steps leading to that have to be backward scheduled accordingly

Sales And Operations Planning Nengu

Supply Chain Graphic Of The Week The S Op Process

What is Sales and Operations Planning (S&OP) and why do you need it?At a recent seminar Steven Thacker explained 👇 TIMESTAMPS (in case you want to skip) 👇Jun 01, 19 · Sales & Operations Planning (S&OP) is the process by which we bring together all the plans for the business (Customers, Sales, Marketing, Development, Manufacturing, Sourcing, and Financial) into one integrated set of tactical plans S&OP gives management the ability to direct its business to achieve a sustainable competitive advantageApr 29, 21 · The Importance of Demand Planning for a Successful Sales and Operation (S&OP) Strategy Demand planning plays an integral role in creating an effective S&OP strategy By using this multistep process, companies are better prepared to anticipate various kinds of demand and factor those demands into the supply chain management process

Sales And Operations Planning S Op Transform Your Business

A Case Method For Sales And Operations Planning A Learning Experience From Germany

Jul 07, · A sales and operations planning (S&OP) process has its limitations Forcing an S&OP process to close the gap between tactical planning and daytoday operations too often leads to compromised results The good news?S&OP is one of the core principles that have played a key role in optimising the supply chain during the last decade This is necessary to create a truly leaPrerequisites Sales & operations planning navigation in OMP;

The Sales And Operations Planning Process In The Context Of Various Download Scientific Diagram

Sales And Operations Planning The Hub Of Your Business Learn About Logistics

OnePlan S&OP is a demanddriven Sales and Operations Planning (S&OP) process focused on creating a centralized, dynamic, integrated business management process that promotes synergy across all key functions of the organization to provide a better plan Traditional S&OP is Static Respond to Market Changes in RealTimeExecutive S&OP Balancing cost, service and cash is a major challenge To improve this supply chain triangle and to steer your organization towards success, a mature Executive Sales and Operations Planning (S&OP) process is key Discover how to turn your current S&OP process into a true scenariobased decisionmaking processJan 14, 21 · S&OP process has been around for a long time Many corporations have tried the S&OP journey with mixed success The process has evolved over the years Each month or planning cycle, the IBP process culminates in a Management Business Review in which the executive team reviews the latest projections, potential gaps in achieving business and

Achieve Excellence In Sales And Operations Planning Sapinsider

Ultimate Guide To Sales And Operations Planning S Op In 21

Http//demandplanningcom//usingexceltopresentupdateforecastsatthedemandreview/ S&OP is a structured monthly process that aligns all functional areas under a unified set of assumptions to enable and coordinate decision making It integrates demand, supply, operations, and financial planning into one game plan for businessJun 01, 19 · S&OP uses include a midrange view (14 months), which provides a company with increased visibility of what is expected to happen Incorporating a better understanding of the demand for our products, as well as improved demand planning and forecasting, will provide better inputs into the S&OP process as we move forwardDec 11, 09 · S&OP – Process Mapping (As~Is / To~Be) 55 S&OP Process Improvement Framework Continuous Improvement Identify Best Practices As~Is Analyse & Evaluate To~Be Implement Business Process Reengineer Business Process Improvement Approaches 56

Oracle Cloud Applications Supply Chain Planning Intro To Sales And Operations Planning Youtube

The Lost Link To Make Strategy Work Sales Operations Planning S Op Strategok By Javier Gonzalez

Sales and Operations Planning (S&OP) is a corporate practice intended to deliver superior supply chain execution by leveraging a deeper alignment with other divisions beyond supply chain most notably sales, finance and production The practice usually revolves around a monthly process starting from the sales forecasts and ending with quantified production plans

Sales And Operations Planning S Op Logistiikan Maailma

Sales And Operations Planning S Op 101 Smartsheet

Integrated Business Planning Ibp S Op Evolution Agile Innovation

Sales Operations Planning Omnics

Pdf Sales And Operations Planning S Op Concepts And Models Under Constraints Literature Review

S Op Process

Sales And Operations Planning Relex Solutions

Implementing An Integrated Sales And Operations Planning Process

S Op Process

Sales And Operations Planning Nengu

What Is S Op How S Op Works Demand Planning Com

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

What Is S Op How S Op Works Demand Planning Com

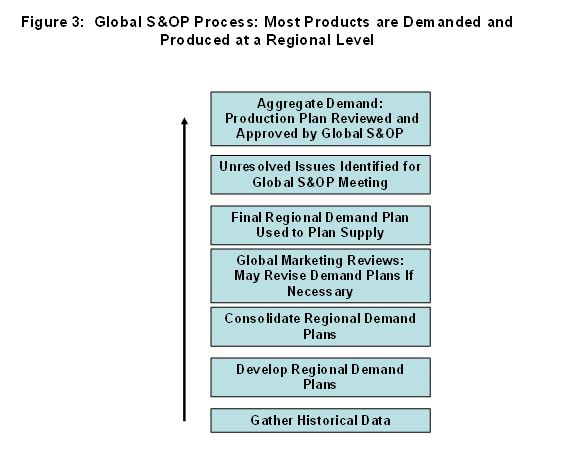

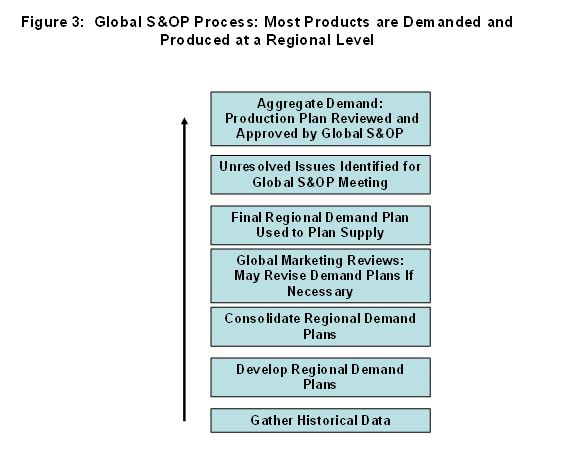

Going Global With Sales And Operations Planning Ppt Video Online Download

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

Executive S Op Case Study Presented At Gpseg

Is Sales And Operations Planning A Digital Age Process Enterra Solutions

Customers Value Chain Connections

Sales Operations Planning S Op An Introduction

S Op Process

Sales Operations Planning Introduction Simply Succeed

Sales And Operations Planning Relex Solutions

Smoother Execution Through S Op Logistics Management

Insights European Gateway Eg Newsroom

Getting To Grips With Sales And Operational Planning Bloor Research

A Comprehensive Overview Of Sales And Operations Planning S Op

Sales Operations Planning S Op An Introduction

Integrating The S Op Process Go With The Flow Business 2 Community

Implement The S Op Process For Supply Chain Success Learn About Logistics

S Op More Important For Planning New Era Supply Chains Learn About Logistics

S Op Process

What Is S Op How S Op Works Demand Planning Com

A Case Method For Sales And Operations Planning A Learning Experience From Germany

Optimise Your Sales And Operations Planning S Op Slimstock Uk

S Op Process

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

Sales And Operations Planning S Op Logistiikan Maailma

Sales Operations Planning Consulting Supply Velocity

Evaluation Of The Maturity Of The S Amp Op Process For A Written Materials Company A Case Study

S Op The Evolving Supply Chain Lifeline Supplychainomics

S Op Effectiveness Recommendations To Make The Leap Sales And Operations Planning Capacity Planning Planning Process

Group50 S Sales And Operations Planning Services By Calling 909 949 90 Emailing Info Sales And Operations Planning Capacity Planning Change Management

Sap Integrated Business Planning Holistic Planning In Short Order Sap Blogs

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

Sales And Operations Planning S Op 101 Smartsheet

Monthly S Op Process Sales And Operations Planning Wikipedia Sales And Operations Planning Best Apps For Teachers Apps For Teachers

Cscmp 14 Bayer Putting The S Back In S Op

Dp Vs S Op Process Flow

Sales And Operations Planning Relex Solutions

Sales And Operations Planning Process Self Assessment

What Is S Op Sales And Operations Planning Explained Anaplan

S Op Process

What Is S Op Sales And Operations Planning Explained Anaplan

Demand Planning Nengu

Sales And Operations Planning Explorescm

Tools Techniques For A Sustainable S Op Cycle Webinar Youtube

Chapter 10 Sales And Operations Planning Aggregate Planning Ppt Download

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Software For Sales Operations Planning In Europe Supply Chain Movement

Sales Operations Planning Two Decades Of Learning At Basf Ppt Video Online Download

19 Gartner Magic Quadrant Sales And Operations System Of Differentiation Arkieva

Top 11 Sales And Operations Planning S Op Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Sales Role In Sales And Operation Planning Demand Planning The Sales Process Blog

Implementing An Integrated Sales And Operations Planning Process

S Op Process Template

Sales Operations Planning Omnics

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Aktuelles Von Aca Solutions Sales And Operations Planning To Industrialize The Aerospace Supply Chain

Sales And Operations Planning Nengu

Implementing An Integrated Sales And Operations Planning Process

Sales Operations Planning A Proven Business Process Learn About Logistics

5 Reasons Why Sales And Operations Planning Is Important Scmdojo

Sales And Operations Planning Report Do You Get Surprises

Aggregate Sales And Operations Planning Ppt Download

Oracle Demantra Sales And Operations Planning User Guide

0 件のコメント:

コメントを投稿